Cellulose insulation is a top pick for those wanting to save energy and help the planet. It’s made from 75 to 85 percent recycled paper, like newspapers and cardboard. This makes it a green choice for homes.

Since the 1950s, it has helped make homes more energy-efficient. It cuts down on heating and cooling costs. This makes homes healthier and fights the fact that 90 percent of US homes are not well-insulated.

By using it right, you can make your home better at keeping warm or cool. It also helps the environment by using materials that would otherwise end up in landfills. Around 62 million newspapers are printed every day, with almost 44 million thrown away. For more info on cellulose insulation, check out here.

Key Takeaways

- Composed of 75 to 85% recycled paper fibers, cellulose insulation is a sustainable choice.

- It offers superior thermal performance compared to fiberglass insulation.

- Approximately 90% of homes in the US lack sufficient insulation.

- Cellulose insulation can help reduce your energy bills significantly.

- It meets low-VOC insulation standards, ensuring a healthier indoor environment.

- This material is effective at soundproofing due to its density.

Understanding Cellulose Insulation

Cellulose insulation is a great choice for homes. It’s made from recycled paper fibers. This makes it good for the planet. It’s used in walls, open spaces, and attics to keep homes warm.

Definition of Cellulose Insulation

Cellulose insulation is mostly made from recycled paper. This includes newspapers and cardboard. It also has fire-safe stuff like borax and ammonium sulfate. This makes it safe and keeps homes warm.

Importance in Energy Efficiency

Cellulose insulation helps homes use less energy. It has a high R-value, which means it keeps homes warm. It can cut down heating costs by 20-30%.

Paragon Protection in Chicago says proper installation is key. It lasts 20 to 30 years. But, it’s not waterproof. So, leaks can hurt its performance.

Raw Materials Used in Cellulose Insulation

Cellulose insulation is great because it’s good for the planet. It’s made from recycled paper. This helps cut down on waste and supports the environment.

Recycled Paper Products

Cellulose insulation is mostly made from recycled stuff. It uses shredded newspapers and cardboard. This helps recycle more and uses less energy.

Every year, 330,000 tons of old newspapers become this green product. It plays a big part in reducing waste.

Additives for Fire Resistance

About 15% to 25% of cellulose insulation has fire-safe stuff in it. Boric acid and ammonium sulfate are often used. They make it safer and keep pests away.

The industry is moving towards cheaper, safer options. This keeps cellulose insulation safe and affordable.

Other Natural Fibers

Cellulose insulation can also have other natural fibers. Cotton insulation, for example, has 85% recycled cotton. Wool and hemp are also used for their special benefits.

Wool makes it better at keeping warm. Hemp is not as common here but works well too.

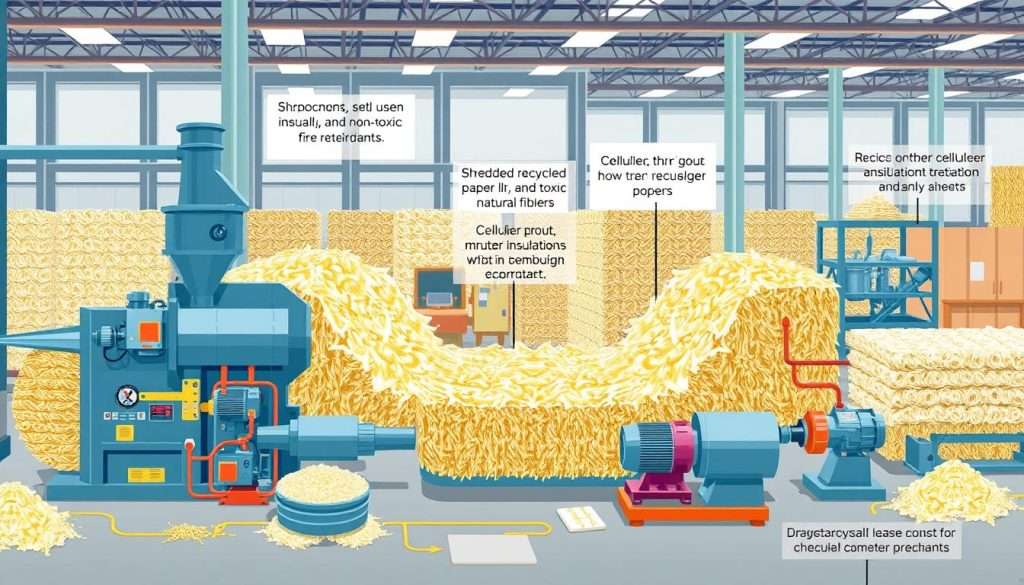

The Production Process of Cellulose Insulation

The making of cellulose insulation starts with using recycled materials. This shows how it’s good for the planet. Each step is made to cut down on waste and keep homes warm.

Collection and Sorting of Paper

First, they collect and sort paper like newspapers and cardboard. This helps the planet and makes money for recycling places. About 80% of cellulose insulation comes from recycled paper, which is great for the environment.

Grinding and Processing Techniques

Then, the paper is ground into small pieces. This makes it ready to insulate well. After that, it’s dried to make it safe and effective.

Cellulose insulation is also safe from fires. It’s UL Class 1 Rated, which means it’s very safe in buildings.

Adding Additives

Next, they mix in special compounds. These help fight fires, keep pests away, and stop mold. This makes the insulation safe for everyone, following green practices.

| Stage | Description | Benefits |

|---|---|---|

| Collection & Sorting | Gathering recycled paper waste | Reduces landfill waste, supports recycling centers |

| Grinding & Processing | Breaking down paper into smaller particles | Improves workability and insulation effectiveness |

| Adding Additives | Mixing in fire-retardant and pest-resistant compounds | Enhances safety and durability |

Benefits of Cellulose Insulation

Cellulose insulation is great for many reasons. It’s made from recycled stuff, which is good for the planet. It helps save energy and is better for the environment.

Eco-Friendly and Sustainable

Cellulose insulation is mostly recycled paper and cardboard. This makes it very eco-friendly. It helps cut down on waste and saves trees.

Using it helps lower carbon emissions. This is better than other insulation options.

Effective Thermal Performance

It has a high R-value, which means it keeps your home warm or cool. This saves you money on energy bills. Your home will be more comfortable.

Soundproofing Qualities

Cellulose insulation is also very good at blocking sound. It can block up to 80% of sound. This is great for homes in noisy areas.

| Benefit | Description | Impact |

|---|---|---|

| Eco-Friendly | Made from recycled materials, reducing waste. | Supports sustainable practices and reduces landfill contributions. |

| Thermal Performance | R-value between 3.1 and 3.8 per inch. | Results in lower energy bills through effective insulation. |

| Soundproofing | Absorbs over 80% of sound. | Improves living conditions in noisy environments. |

Common Applications of Cellulose Insulation

Cellulose insulation is used a lot in homes and businesses. It’s good for the planet and saves energy. People like it because it’s green and works well.

Residential Uses

In homes, cellulose insulation is very useful:

- Attics: It makes attics more energy-efficient and keeps temperatures steady.

- Walls: Putting it in walls makes them better at keeping heat in and cold out.

- Floors: It stops drafts and keeps the floor warm.

- Ceilings: It helps keep heat in and makes rooms more comfortable.

Using cellulose insulation can cut down heating and cooling costs by 25%. This saves money over time and is good for the planet.

Commercial Uses

Cellulose insulation is also great for businesses:

- New Constructions: It’s used in new buildings for its great insulation and green benefits.

- Retrofitting: It’s good for old buildings too, making them more energy-efficient.

Big spaces in businesses need to stay at a good temperature. Cellulose insulation helps keep that temperature steady.

Comparison with Other Insulation Materials

When picking insulation for your home, it’s key to know the differences. Cellulose insulation vs fiberglass shows big differences in being green, easy to install, and how well they keep heat. We’ll look at how fiberglass and spray foam compare to cellulose.

Fiberglass Insulation

Fiberglass is the top pick for homes. It’s made from sand and glass. Cellulose, on the other hand, comes from recycled newspaper. Here’s a side-by-side look:

| Feature | Fiberglass Insulation | Cellulose Insulation |

|---|---|---|

| R-Value per inch | 2.2 to 2.7 | 3.2 to 3.8 |

| Environmental Impact | Less green, needs a lot of energy | Green, made from recycled stuff |

| Installation | Easy for DIY, needs gloves and gear | Easy to install, might settle |

| Fire Resistance | Not flammable, no extra treatment needed | Needs fire retardants, might be flammable if not treated |

| Moisture Retention | Keeps more moisture, might clump | Keeps less moisture, might clump |

| Cost | Lower cost upfront | Higher cost, varies by square foot |

Spray Foam Insulation

Spray foam insulation seals air well but costs more. Here’s how it compares to cellulose:

| Feature | Spray Foam Insulation | Cellulose Insulation |

|---|---|---|

| R-Value per inch | 3.5 to 3.7 | 3.2 to 3.8 |

| Longevity | Lasts over 30 years | Lasts 20 to 30 years |

| Cost | More expensive per square foot | Less expensive per square foot |

| Installation Difficulty | Needs special equipment | DIY friendly with the right knowledge |

| Toxicity | Toxic if eaten, needs thermal barrier | Safe when installed right |

This insulation material comparison shows cellulose often beats others in being green and keeping heat. Picking insulation is a big choice that should match your home’s needs and values.

Installation Methods for Cellulose Insulation

When you think about putting in cellulose insulation, knowing the insulation techniques is key. There are two main ways: the blowing method and the wet-spray method. Each has its own perks and fits different needs, making sure your insulation works well.

Blowing Method

The blowing method uses a special machine to blow cellulose into spaces. It fills gaps and voids well. This method is great for attics and walls, making them more energy-efficient.

The R-value of loose-fill cellulose insulation is about 3.5 per inch. This beats traditional fiberglass, which is usually between 2.2 and 2.7 per inch.

- Uses a machine to spread insulation

- Works well on existing buildings

- Boosts thermal resistance and cuts down on air leaks

Wet-Spray Method

The wet-spray method adds moisture during installation. This makes the cellulose stick better. It’s best for new buildings where walls can be insulated before they’re sealed.

It’s crucial to wear protective gear like N95 masks and safety glasses during installation. This keeps workers safe.

- Moisture helps it stick and reduces settling

- Great for new buildings

- Needs careful handling to avoid too much moisture

Both methods help cellulose insulation slow down heat and make your home more comfortable. For more info on how to install, check out this resource. Knowing these insulation techniques helps you make smart choices for your home’s energy use.

Maintenance and Longevity of Cellulose Insulation

Keeping cellulose insulation in good shape is key. It usually lasts 20 to 30 years. But, how long it lasts depends a lot on moisture.

To make your insulation last longer, you need to know how to take care of it.

Lifespan Expectations

Cellulose insulation settles over time. This can make it less effective. But, it still keeps your home warm or cool well.

Getting it installed by a pro helps it settle less. This means it works better for longer.

Signs of Wear and Tear

Spotting problems early helps your insulation last longer. Look out for:

- Mold growth – This means there’s too much moisture.

- Settling – If it looks thinner than before, it’s settling.

- Reduced R-value – If you’re using more energy, it might not be doing its job.

Checking it often and taking care of it is important. Keeping moisture out helps a lot. This way, your insulation works well for years.

Cost Considerations

Homeowners need to know the costs of cellulose insulation before installing it. The price per square foot is between $0.60 and $4.20. This depends on how it’s installed and other factors. Cellulose insulation is a good choice because it saves money on energy.

Average Cost per Square Foot

The costs are as follows:

| Insulation Type | Cost per Square Foot |

|---|---|

| Cellulose (Blown-in) | $0.60 – $4.20 |

| Fiberglass (Blown-in) | $1.00 – $2.80 |

| Rockwool (Blown) | $1.90 – $4.20 |

Long-Term Savings on Energy Bills

Cellulose insulation is not just affordable. It also saves money over time. It helps keep your home warm in winter and cool in summer. This means lower bills for heating and cooling.

Many people see their money back in a few years. This makes cellulose insulation a smart choice.

Conclusion: Is Cellulose Insulation Right for You?

Let’s talk about choosing cellulose insulation for your home. It’s important to think about energy savings, cost, and comfort. If you want something green and affordable, cellulose insulation is great. It has a high R-value, making it a top choice for keeping your home warm.

Evaluating Your Insulation Needs

Before you decide, check your home’s insulation. You might need 1,000-1,500 pounds for a house. Make sure your home is ready for new insulation. Also, think about how cellulose can make your home quieter and healthier.

Final Thoughts on Cellulose Insulation

Cellulose insulation is a smart pick. It’s good for the planet, lasts a long time, and blocks sound well. Talking to an insulation expert can help you see if it’s right for you. They can also help with any setup problems.